10 Essential Tips for Choosing Fibrous Salami Casing?

Choosing the right fibrous salami casing is crucial for producers aiming for quality. According to a report by the Institute of Meat Technology, over 70% of consumers prefer salami that is flavorful and retains moisture. This underscores the importance of selecting the ideal casing material. Renowned industry expert Dr. Mark Halperin states, "The right casing can make or break your salami." This emphasizes the need for careful consideration in the selection process.

When evaluating options, factors like permeability, strength, and compatibility with filling should be top priorities. Fibrous casings are known for their durability and ability to retain the salami's profile during the drying process. However, not all options deliver the same results. A report indicates that improper casing selection can lead to product spoilage and consumer dissatisfaction.

In a market rich with choices, producers must weigh the benefits and drawbacks of each type. Careless decisions can lead to less-than-ideal outcomes. It's essential to stay informed and thoughtful about these fundamental choices. Making an informed decision on fibrous salami casing will significantly affect the final product's quality and success.

Factors Influencing the Selection of Fibrous Salami Casings

Choosing the right fibrous salami casing can significantly impact the final product. Several factors need attention. One key consideration is the diameter of the casing. A larger diameter may mean more product, but it can affect cooking times and texture. Fibrous casings come in various sizes. Therefore, your choice should align with the type of salami being made.

Moisture retention is another critical aspect. Some casings hold moisture better than others. This can influence the flavor and shelf life of the salami. Try testing different types to see which works best for your recipes. Additionally, think about the casing's strength. A strong casing will withstand stuffing and cooking processes. Conversely, a weak casing can lead to breakage, impacting product quality.

Texture and color also play a role. Select a casing that complements the salami's characteristics. Different casings can yield different textures. It's not merely about function; it’s about the overall aesthetic appeal. Pay attention to these details, as they can lead to unexpected results. Don't hesitate to experiment; each choice is a learning opportunity.

10 Essential Tips for Choosing Fibrous Salami Casing

| Tip No. | Tip | Description | Considerations |

|---|---|---|---|

| 1 | Material Quality | Choose high-quality fibrous materials for durability. | Look for certifications or standards. |

| 2 | Diameter Size | Select casing diameter based on desired salami size. | Consider target market preferences. |

| 3 | Moisture Resistance | Ensure casing can withstand moisture during processing. | Check product specifications. |

| 4 | Shrinkage Rate | Assess how much casing shrinks during cooking. | Understand the impact on final product appearance. |

| 5 | Color Options | Choose colors that enhance product appeal. | Align with branding guidelines. |

| 6 | Thickness | Select the thickness for optimal texture. | Research texture preferences of your target audience. |

| 7 | Compatibility with Fillings | Make sure casing works well with various fillings. | Consider various salami recipes. |

| 8 | Ease of Use | Select casings that are easy to handle. | Train staff properly for best results. |

| 9 | Price | Evaluate cost-effectiveness of different casings. | Balance quality with budget. |

| 10 | Supplier Reputation | Research suppliers for reliability and service. | Request references and reviews. |

Understanding Different Types of Fibrous Casings Available in the Market

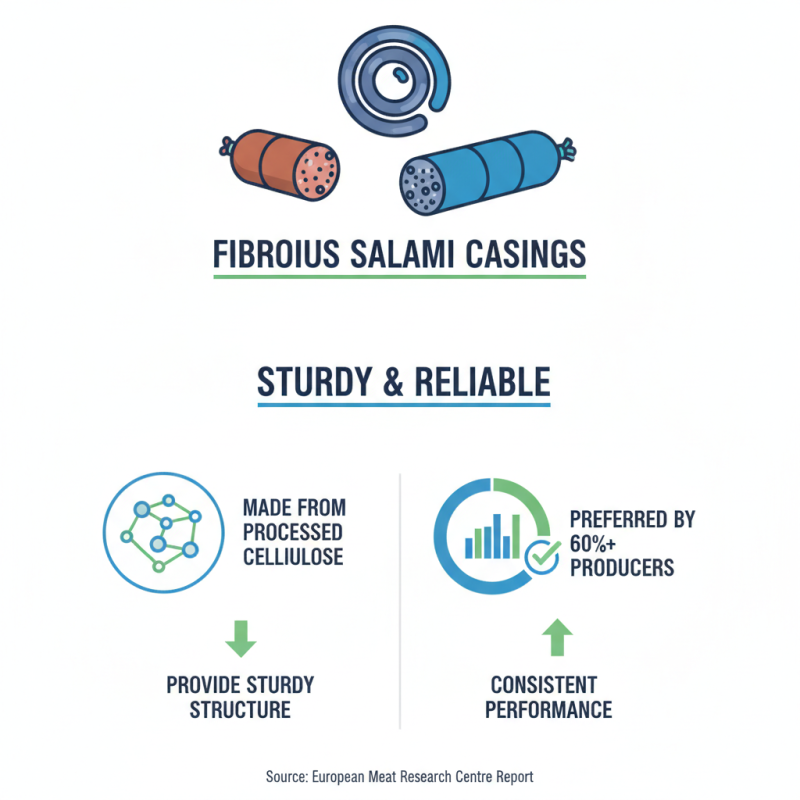

When it comes to fibrous salami casings, understanding the variety available can be overwhelming. Fibrous casings are made from processed cellulose and provide a sturdy structure for sausages. A report from the European Meat Research Centre highlights that over 60% of sausage producers prefer fibrous casings due to their reliability and consistent performance.

There are several types of fibrous casings in the market. Some are designed for cold smoking, while others withstand hot cooking processes. The thickness of these casings can vary significantly. Thinner casings are perfect for products that require a softer texture. Conversely, thicker options offer better durability and shelf life. Numerous manufacturers often struggle with achieving the right diameter for their products. This can lead to wasted time and resources.

A common misconception is that all fibrous casings are the same. In reality, factors like permeability and tensile strength are critical to the overall quality of the final product. For instance, a report by the Food and Agriculture Organization mentions that proper permeability allows moisture and smoke to penetrate effectively. Choosing the right casing impacts flavor and texture. Some producers find themselves regretting decisions made in haste. It is crucial to evaluate your specific needs and product goals thoroughly.

Evaluating Thickness and Strength: Key Specifications for Quality Casings

Choosing the right fibrous salami casing is essential for crafting quality products. Thickness plays a critical role in this decision. A thicker casing can offer better protection during the curing process. However, extreme thickness can influence the final texture. The ideal thickness allows for proper fat distribution, enhancing overall flavor.

Strength is another key specification to evaluate. A robust casing can withstand stuffing without tearing. This strength is vital during the cooking or smoking phases, ensuring that the casing retains its integrity. Weak casings might lead to loss of moisture, impacting taste. Evaluating these properties requires careful consideration. Visual inspection can give clues, but scientific measurement is often necessary for accuracy.

Feel free to experiment with different thicknesses and strengths to find what works best. Sometimes, a casing may look perfect but fail during processing. Don't hesitate to adjust and reflect on your choices. The perfect salami is often a product of trial and error.

Thickness and Strength of Different Fibrous Salami Casings

The Importance of Breathability in Fibrous Salami Casing Performance

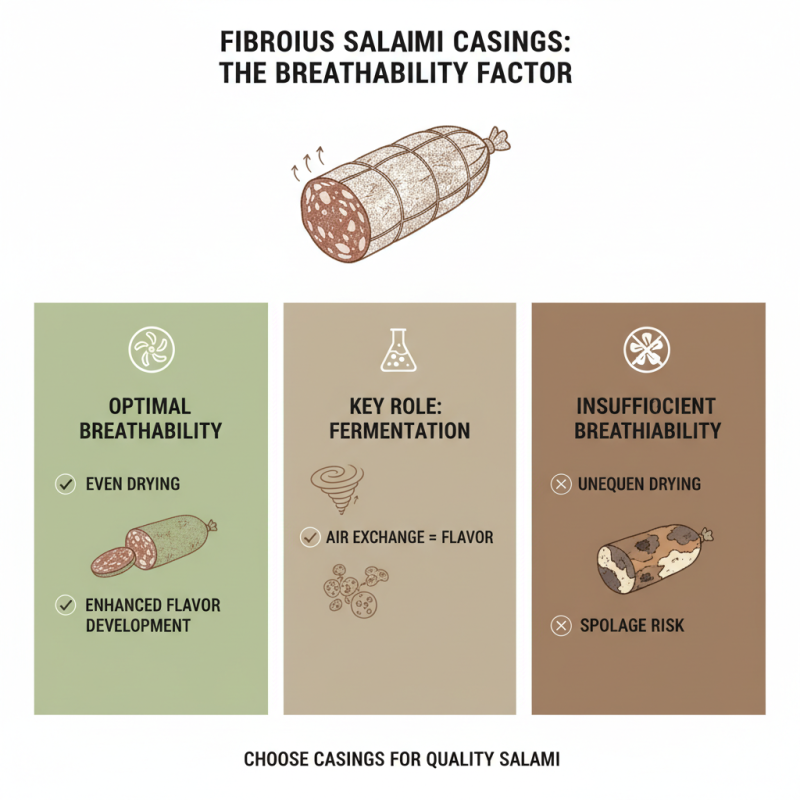

When selecting fibrous salami casings, breathability plays a crucial role. If the casing lacks proper airflow, the salami process can be compromised. Insufficient breathability can lead to uneven drying and spoilage. This is especially important during fermentation, where air exchange affects flavor development.

A well-breathable casing ensures that moisture escapes efficiently. For example, too much moisture retention can lead to mold growth or an off-flavor. This highlights the delicate balance needed in the production process. Sometimes, even slight variations in the casing's composition can affect breathability.

Inspecting the casing's structure can reveal a lot. A smooth surface may seem ideal, but small pores contribute to better airflow. Not all casings are created equal. Each choice brings unique challenges. A thoughtful approach is necessary, considering how each factor influences the final product.

Best Practices for Storing and Handling Fibrous Salami Casings

When handling fibrous salami casings, proper storage and management are crucial for quality. A 2021 report from the Meat Industry Research Council highlighted that improper storage can lead to significant quality loss. Ideal conditions require a cool, dry environment. Maintaining a temperature between 32°F to 39°F is essential. Direct sunlight should be avoided.

Additionally, moisture control is vital. Casings should be left in air-tight containers to prevent exposure. A humidity level of around 60% is recommended for long-term storage. Many users neglect this aspect, leading to compromised integrity. Regular inspection is advised to catch any signs of mold or degradation. These small details often make the difference between an excellent product and a subpar one.

Fibrous casings need careful handling as well. Using clean utensils prevents contamination during preparation. Observing cleanliness reduces the risk of spoilage. Surprisingly, many in the industry overlook these basic practices. It’s important to remind oneself of the foundational aspects that impact quality. A small mistake in handling can affect the final taste and texture significantly.

Related Posts

-

What is Clear Fibrous Casings and How Are They Used in Food Industry

-

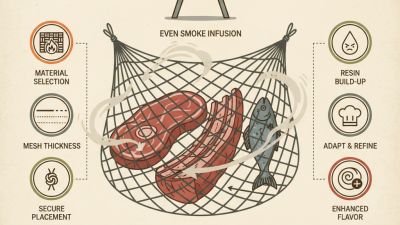

How to Use a Net for Smoking Meat in 2026?

-

Best Meat Nets for Perfect Grilling Results in Your Backyard

-

What is the Best Net for Cooking Meat for BBQ and Grilling

-

10 Essential Tips for Using Cellulose Casing in Sausage Making?

-

Top Plastic Casings in Technology and Their Applications?