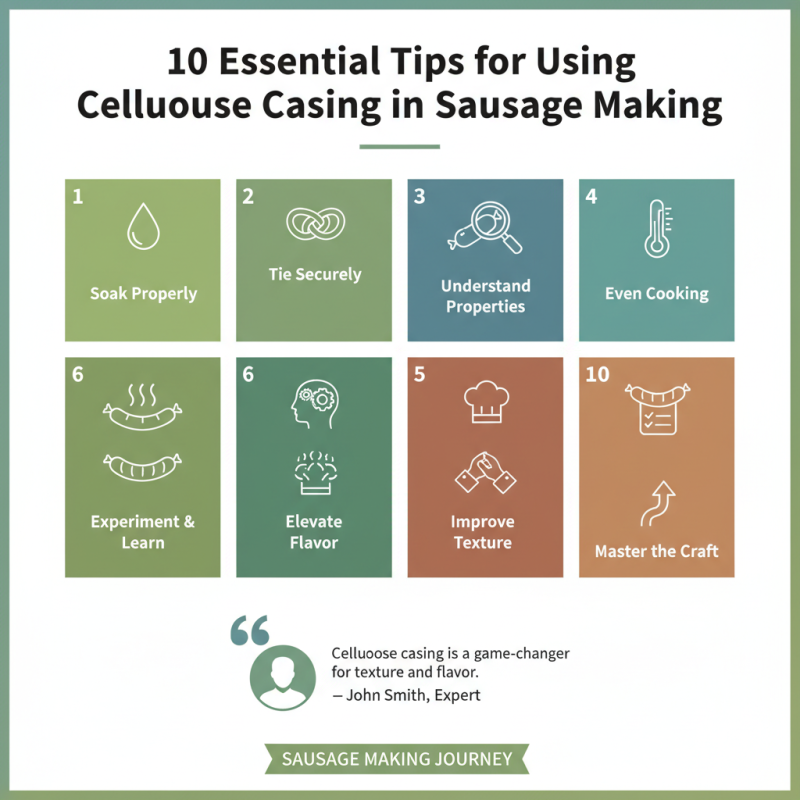

10 Essential Tips for Using Cellulose Casing in Sausage Making?

In the world of sausage making, mastering cellulose casing can elevate your craft. According to expert John Smith, "Cellulose casing is a game-changer for texture and flavor." This material offers unique benefits that can enhance your sausage-making experience.

Many new sausage makers struggle with cellulose casing. Common mistakes include improper soaking and inadequate tying techniques. These errors can lead to disappointing results. Understanding the properties of cellulose casing is essential. It provides great stability and allows for even cooking.

Moreover, the choice of cellulose casing can influence the final product. For instance, the diameter affects the cooking time and flavor absorption. There is a degree of trial and error involved. Reflecting on your own experiences can lead to better results. Embracing the learning process is part of the journey in mastering cellulose casing.

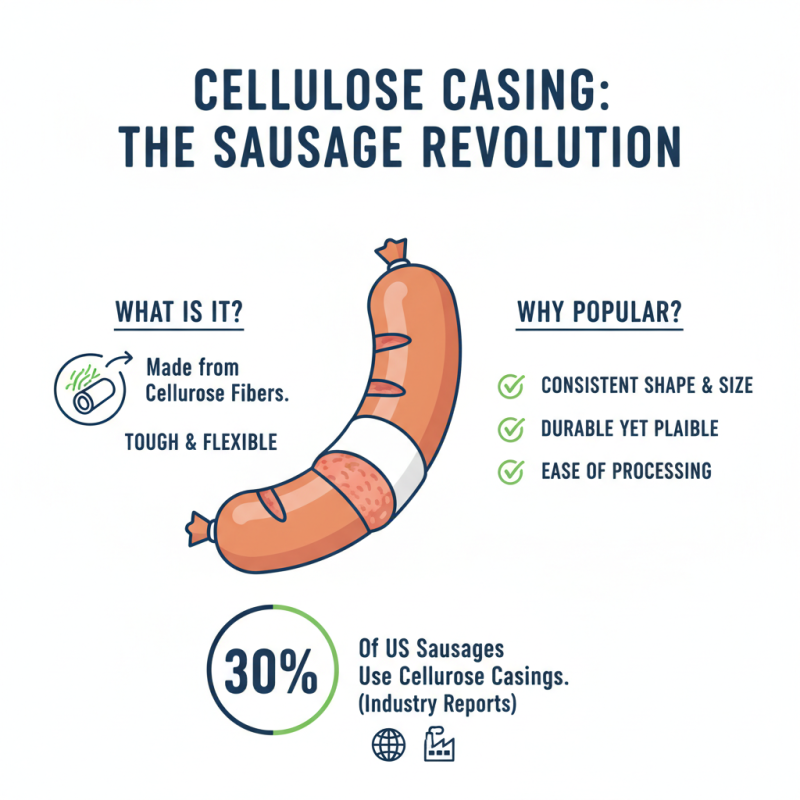

Understanding Cellulose Casing and Its Benefits in Sausage Making

Cellulose casing has gained popularity in sausage making due to its unique benefits. This type of casing is made from cellulose fibers, offering a tough, yet flexible solution for encasing sausages. According to industry reports, nearly 30% of sausages produced in the U.S. use cellulose casings, thanks to their ability to provide a consistent shape and size.

Using cellulose casings can enhance product quality. They are non-permeable, which means no moisture escapes. This helps preserve flavor and juiciness. A key benefit is that cellulose casings can be peeled off easily, providing a clean presentation. This factor is becoming crucial as consumers lean toward visually appealing products.

Here are some tips for optimal use: Ensure proper temperature control during smoking and drying. Maintaining the right environment prevents spoilage. Try experimenting with different flavors during the initial mixing stage. Additionally, avoid overstuffing the casings to prevent bursting. Many producers overlook this step but keeping an eye on casing tension is vital. Avoiding these pitfalls can lead to better sausages that meet consumer expectations.

Choosing the Right Type of Cellulose Casing for Your Sausages

Choosing the right type of cellulose casing is crucial for successful sausage making. These casings come in various sizes and thicknesses, which significantly impact texture and flavor. Data indicates that nearly 70% of vendors encounter challenges with casing choice. Factors like moisture permeability and cooking characteristics are vital for preserving freshness.

Selecting the wrong casing can lead to serious quality issues. For instance, a too-thick casing might create a tough bite, while a too-thin casing may burst during cooking. According to industry studies, over 30% of sausages are discarded due to improper casing choices. These statistics highlight the importance of testing different casings before committing to a large batch.

When choosing cellulose casings, consider the sausage type and desired flavor profile. Experiment with different options to find what works best. Don't shy away from asking for feedback. Tracking your sausage-making results can provide valuable insights. Embrace the learning process; there’s always room for improvement.

10 Essential Tips for Using Cellulose Casing in Sausage Making

| Tip Number | Tip | Details |

|---|---|---|

| 1 | Choose the Right Diameter | Select a casing diameter that suits the type of sausage you are making. |

| 2 | Soak the Casings | Soak cellulose casings in warm water for 30-60 minutes before use. |

| 3 | Use a Proper Stuffing Machine | Ensure you have a good sausage stuffer for even filling and better results. |

| 4 | Maintain Consistent Pressure | Keep a steady pressure during stuffing to avoid air pockets. |

| 5 | Tie the Ends Securely | Ensure both ends are tightly tied to prevent leaks. |

| 6 | Consider the Texture | Different cellulose options can affect the sausage's texture. |

| 7 | Choose the Right Flavor | Select casings that complement the flavor profile of your sausage. |

| 8 | Test for Moisture | Ensure moisture content in filling is optimal for best casing performance. |

| 9 | Monitor Cooking Temperature | Cooking temperature must be properly monitored to prevent bursting. |

| 10 | Store Properly | Store casings in a cool, dry place to extend shelf life. |

Step-by-Step Guide to Preparing Cellulose Casing for Use

Preparing cellulose casing for sausage making can elevate your creations. Start by soaking the cellulose casings in warm water for about 30 minutes. This makes them more pliable and easier to work with. Industry reports indicate that proper hydration can significantly improve the texture of the final product.

When filling the casings, keep the air pockets to a minimum. This can be challenging, especially for beginners. Use a filling tube that fits the casing well. Tips suggest filling slowly and gently to ensure the sausage maintains its shape. If you notice air bubbles forming, you can prick them with a needle, but exercise caution. Too many holes can lead to leaks.

After filling, tie off the ends securely. Make sure to leave some space on both ends; this allows for expansion during cooking. Monitor the cooking process closely. Overcooked sausages can split open, ruining their appearance and texture. Remember, while cellulose casings provide a uniform look, achieving the perfect sausage takes practice. Don’t hesitate to experiment and learn from mistakes along the way.

Techniques for Stuffing Sausages with Cellulose Casing

Stuffing sausages with cellulose casing can be a unique experience. The right technique is critical for achieving a great finish. Start by selecting a suitable diameter for your cellulose casing. It should match the size of the stuffing tube. A mismatch can lead to issues, like breakages or uneven fills.

Preparing the mixture is equally important. Ensure the meat is well-blended and seasoned. Too much air in the mixture can cause problems. Some air pockets may lead to bursting during cooking. When you begin to stuff, maintain consistent pressure on the casing. This helps to avoid any gaps. Monitor your fill rate, as overstuffing can lead to uneven cooking.

After stuffing, twist the sausages at regular intervals to create links. A common mistake is not twisting tightly enough. This can cause the sausages to separate later. Use ties for extra security if needed. Pay attention to the ends of the casings; secure them well. Don’t forget to prick the sausages before cooking. This reduces the risk of bursting during the cooking process. These simple techniques can enhance your sausage-making journey.

10 Essential Tips for Using Cellulose Casing in Sausage Making

Cooking and Storing Sausages Made with Cellulose Casing

When cooking sausages made with cellulose casing, it's important to follow a few key tips. First, avoid high temperatures during cooking. It can cause the casing to burst. Instead, cook sausages at a low, steady heat. This method ensures even cooking and prevents loss of moisture. Sear the sausages briefly for added flavor.

Storing your sausages properly is crucial for maintaining their quality. Cool them to room temperature before refrigeration. Place them in airtight containers or vacuum-sealed bags. This prevents freezer burn and preserves flavor. Remember, cellulose casing doesn’t retain moisture like natural casing does. Thus, check the texture regularly.

Sometimes, the texture can feel off. Reflections on the cooking process can help adjust future batches. If your sausages feel tough or dry, consider lowering the cooking temperature next time. Practice will improve consistency. Always taste test before serving. Proper handling makes a noticeable difference.

Related Posts

-

What is Clear Fibrous Casings and How Are They Used in Food Industry

-

10 Best Tips for Using Cooking Meat Netting to Enhance Flavor and Presentation

-

Top 10 Netted Meat Recipes You Must Try for Flavorful Dishes

-

2026 Top Meat Nets Trends and Innovations in the Food Industry?

-

Best Meat Nets for Perfect Grilling Results in Your Backyard

-

What is the Best Net for Cooking Meat for BBQ and Grilling