Top Plastic Casings in Technology and Their Applications?

In today's technology-driven world, plastic casings play a vital role across various industries. Experts like Dr. Emily Tran, a leading authority in materials science, emphasize their importance. She once stated, "Plastic casings provide protection and versatility crucial for electronic devices." This highlights the essential role they play in safeguarding technology.

From smartphones to medical equipment, plastic casings are everywhere. Their lightweight nature and durability make them ideal for many applications. This versatility allows manufacturers to innovate, yet it also raises questions about long-term sustainability. Can we rely on them in the future?

While plastic casings are beneficial, they present challenges, too. Increased usage has led to environmental concerns. As we embrace these materials, we must reflect on their lifecycle. How can we improve recycling methods? Balancing innovation with sustainability is essential for a better tomorrow.

Overview of Plastic Casings in Technology

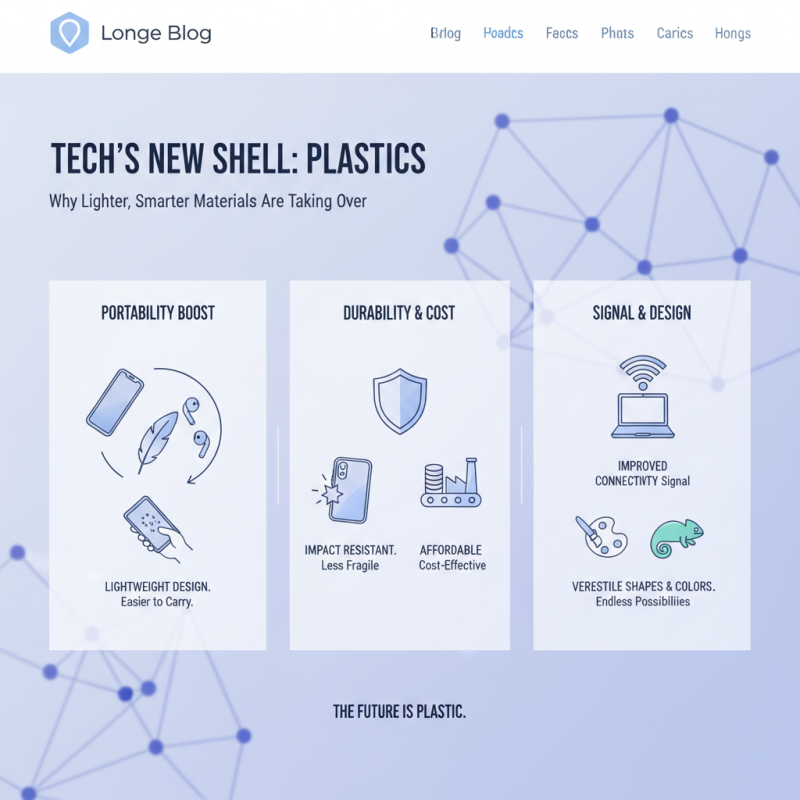

Plastic casings play a crucial role in technology today. They house various electronic devices, providing protection and structure. These casings are lightweight and can be molded into different shapes, making them versatile. Many consumer electronics use plastic casings. They are found in smartphones, laptops, and home appliances, enhancing aesthetics and functionality.

Creating a plastic casing involves careful material selection. Different types of plastics offer varying benefits. Some are more durable, while others allow for better heat dissipation. Choosing the right material is vital for the device's longevity. One must reflect on these choices, as the wrong plastic can lead to early wear and tear.

Tips: Always consider recycling when choosing plastic casings. Many materials can be repurposed effectively. Reducing waste should be a priority. Be aware of how your choices impact the environment. Balancing performance with sustainability is a challenge but worth pursuing. Developing a responsible mindset is essential in technology design.

Types of Plastics Used for Casings

When discussing the types of plastics used for casings in technology, several materials stand out. Polycarbonate, for instance, is well-known for its durability and transparency. It makes cases that resist impacts and scratches. A recent industry report indicates that polycarbonate demand is projected to rise by 6% annually. This growth highlights its importance in consumer electronics.

Acrylonitrile Butadiene Styrene (ABS) is another popular choice. It offers flexibility and strength, making it suitable for various applications. ABS casings are common in toys and household appliances. Data shows that the ABS market is expected to expand due to increasing consumer interest in sustainable products. However, there are environmental concerns regarding its production and disposal.

Polypropylene, valued for its chemical resistance, is also widely used. It is lightweight and cost-effective, suited for automotive and medical applications. The global polypropylene market is predicted to grow steadily, reaching significant values by mid-decade. Yet, it's crucial to reflect on the recycling challenges associated with these materials, as many are not biodegradable. Developing better recycling processes should be a priority for the industry.

Top Plastic Casings in Technology and Their Applications

| Type of Plastic | Properties | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Strong, impact-resistant, and lightweight | Consumer electronics, automotive interiors | Good thermal stability and ease of machining | Lower chemical resistance compared to other plastics |

| PC (Polycarbonate) | High impact resistance, transparency, and heat resistance | Safety glasses, electronic housings | Excellent clarity and toughness | Can be prone to scratching |

| PP (Polypropylene) | Chemical resistant, flexible, and lightweight | Packaging, automotive parts | High fatigue resistance and recyclable | Lower toughness compared to others |

| PVC (Polyvinyl Chloride) | Durable and resistant to environmental degradation | Pipes, electrical cable insulation | Versatile and inexpensive | Can emit harmful gases when burned |

| POM (Polyoxymethylene) | High rigidity, low friction, and wear resistance | Precision parts, gears, and bearings | Excellent dimensional stability | Not UV resistant |

Key Applications of Plastic Casings in Electronics

Plastic casings play a crucial role in the electronics industry. They provide an essential protective layer for devices, safeguarding sensitive components from damage. Many electronic devices endure harsh conditions. High temperatures or moisture can lead to failures. Plastic casings help to mitigate these risks, offering a lightweight and durable solution.

In consumer electronics, plastic casings are prevalent. Smartphones and laptops often incorporate plastic elements for enhanced portability. These materials are also easier to mold into intricate designs, enhancing aesthetics. However, not all plastics are created equal. Choices must be made carefully, as some plastics may degrade over time. This could lead to device failure or aesthetic issues, like discoloration.

The automotive industry also relies heavily on plastic casings. Many vehicle components are housed in plastic to reduce weight and improve fuel efficiency. Yet, pollution from plastics remains a notable concern. Manufacturers might need to rethink their material choices. Sustainable options could emerge as more viable long-term solutions in the future.

Advantages of Using Plastic Casings Over Other Materials

Plastic casings are increasingly popular in technology. They offer unique benefits that make them a preferred choice over metals or glass. One of the primary advantages is their lightweight nature. Plastic casings reduce the overall weight of electronic devices, making them easier to handle. This is crucial for portable gadgets that users carry daily.

Additionally, plastic is resistant to corrosion and environmental factors. Devices made with plastic can withstand moisture and dust better than their metal counterparts. However, some plastics can degrade with prolonged exposure to UV light. This drawback requires careful selection of materials for specific applications.

Moreover, plastic casings allow for versatile designs. Manufacturers can mold them into various shapes and sizes. This flexibility opens up opportunities for innovative designs that enhance functionality. Of course, one must consider the recycling challenges associated with plastic. It's essential to balance the benefits and drawbacks when choosing materials.

Future Trends in Plastic Casing Technology

The evolution of plastic casing technology is fascinating. The industry is projected to grow significantly. By 2025, the global plastic casing market is expected to reach approximately $10 billion. This growth reflects advancements in materials and manufacturing techniques. Lightweight, durable, and flexible materials are being prioritized.

Sustainability plays a critical role in future trends. The rise of biodegradable plastics is noteworthy. These eco-friendly alternatives can reduce environmental impact. Reports suggest that the biodegradable plastics market will grow by over 20% annually. Yet, challenges remain in scalability and performance. Many companies are still hesitant to fully transition due to production costs and supply chain issues.

Smart technology integration is another area of interest. The demand for smarter devices is on the rise. As a result, casings that can support IoT applications are essential. However, embedding sensors and communication tools into plastics can complicate manufacturing processes. It requires new approaches that might not always yield consistent results. Balancing innovation and reliability will be crucial in the coming years.

Top Plastic Casings in Technology and Their Applications

Related Posts

-

10 Best Tips for Using Cooking Meat Netting to Enhance Flavor and Presentation

-

Top 10 Netted Meat Recipes You Must Try for Flavorful Dishes

-

10 Essential Tips for Using Mahogany Fibrous Casings Effectively

-

What is Clear Fibrous Casings and How Are They Used in Food Industry

-

What is the Best Net for Cooking Meat for BBQ and Grilling

-

Best Meat Nets for Perfect Grilling Results in Your Backyard